INSTALLATION INSTRUCTIONS-FO-D1003 ADJUSTABLE FRONT TRACK BAR

Place vehicle on level ground with the wheels blocked, parking brake set.

Remove the ball stud at the frame end of the OEM track bar. Remove the cotter pin from castle nut, remove nut (22mm wrench). Hit the casting with a hammer to remove the stud from the frame. Remove the bolt (18mm wrench) and nut from the axle end of the OEM track bar.

Pull the track bar free of the vehicle. Retain bolt and nut clip for re-installation of the new Dodge Off Road Track Bar. Some 94-95 models have a bolt-on brace from the engine cross-member to the cast track bar mount. Remove and discard this brace. Unbolt the brake line clip from the cross-member. Some 94-95 models use a small ball stud.

The tapered OEM cast frame bracket must be drilled out to 5/8” to accept the new bracket bolt.

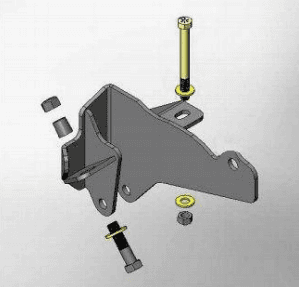

Mount the new track bar bracket to the frame with a 5/8” x 2-1/2” bolt and locknut. Install the 1/2” x 5” bolt down thru the existing frame hole under the steering box input shaft, then thru the front ear on the FO bracket. Secure with 1/2” locknut. The head of the bolt will sit at a weird angle. This is okay, so just tighten the nut, but do not crush the frame.

With the FO track bar bracket positioned, use the bracket as a drill guide and drill thru the crossmember under the engine with a 9/16” drill bit. Drill all the way through both sides. Install the 9/16” x 3” bolt through the bracket and crossmember, and secure with a 9/16” locknut. Drill pilot hole in cross-member to reattach brake line.

Track Bar Assembly Install

Bolt up the end at the axle first, using the stock bolt and nut. If you need to replace your stock bolt and nut, use a 14mm or 9/16” bolt that is 3” long. Check your axle mount holes for elongation (oval shaped), and if you find the bolt is loose in the mount, you may need to fix this with a weld washer. Torque spec for this bolt is 150 ft/lbs. Raise the track bar into position and bolt the other end into the frame bracket using the misalignment spacers. You will adjust the track bar length once both ends are bolted in and tightened down. Torque spec for this bolt is 180 ft/lbs. For lifted trucks, on the passenger side you may need to grind a notch in the spring bucket gusset right above where the track bar will pass so the track bar will not hit the gusset. Remove as much material as needed to ensure that the track bar does not contact the bracket when your suspension is at full droop.

Centering Front Axle

An alignment shop will be able to get the front axle positioned much more accurately (HIGHLY RECOMMENDED), however if you want to center the axle yourself, you only need to find a common point on both sides of the axle and then use a plumb bob to gauge how those spots sit under the frame on both sides. The easiest thing to do is to watch your sway bar end links and see when they both have the same angle, but keep in mind that the sway bar can move around inside its frame mounts, so this method is not bullet-proof. Your shocks can also show you if the axle is not centered. If the track bar is not perfectly centered, the only ill-effects are the tires might rub on one side but not the other. You can drive like this until you are able to get an alignment. Adjusting the track bar is very easy. Just loosen the jam nuts and then the bar will rotate while still mounted on the truck. Once you have centered the axle, tighten the jam nuts down.

Final Notes

Recheck that all fasteners are properly tightened. Check all areas around the track bar for interference. The installation of the FO track bar does not alter your alignment’s toe measurement; however you will notice that the steering wheel is off-center. There is an adjusting sleeve on the stock drag link that can be loosened using a 15mm socket and then you turn the sleeve to adjust the steering wheel. This can be time consuming, and an alignment shop will be able to get it done quickly and accurately. It is ultimately the buyer’s responsibility to have all bolts and nuts checked for tightness after the first 500 miles and then every 1000 miles. Just like checking your lug nuts or anything else, you should make it a habit to monitor critical items on your truck periodically.

INFO@FREEDOMOFFROADUSA.COM

919-590-0329